Are you feeling the squeeze from rising component costs? Big-name memory brands can eat into your margins, making it hard to stay competitive. It’s a tough spot to be in.

Yes, for many consumer electronics, emerging Chinese memory brands1 are a reliable and cost-effective alternative. They often comply with global JEDEC standards2, offering a strong price-performance ratio3 that makes them a solid Plan B for managing your procurement budget4 and supply chain risks5.

I get it. The words "emerging Chinese brand" can sometimes raise eyebrows, especially in the world of electronic components where reliability is everything. For over 20 years, I've seen clients hesitate, worried about quality, compatibility, and the risks of the unknown. But I've also seen how a smart, calculated decision to test these alternatives can transform a project's profitability. Let's break down the reality behind these brands and see where they truly fit in your supply chain. It's time to look past the prejudice and focus on the practical benefits.

Do Chinese Memory Brands Meet Global Quality Standards?

Worried about quality and compatibility? You can't risk using components that don't meet the industry standards your designs depend on. A single bad part could derail your entire production line6.

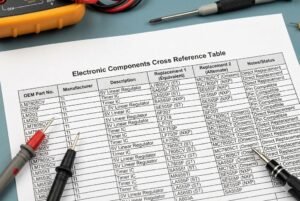

Yes, many emerging Chinese memory manufacturers design their products to be fully compliant with JEDEC standards2. This ensures their memory chips, like NAND flash or DDR, have the same physical footprint, pinout, and electronic interface as parts from major brands, making them a direct replacement.

Let's dive a little deeper into this. The fear of poor quality is understandable, but the landscape of Chinese manufacturing has changed dramatically. It's no longer just about low-cost copies. There has been a massive investment in technology, quality control7, and R&D.

What is JEDEC and Why Does It Matter?

JEDEC is the global leader in developing open standards for the microelectronics industry. When a memory chip is JEDEC-compliant, it means it follows a universal set of rules for how it's built and how it communicates. For you, this means interoperability. You can design a circuit board for a JEDEC-standard eMMC, and in theory, any JEDEC-standard eMMC from any manufacturer should work in that slot. This is crucial because it prevents you from being locked into a single supplier. Many Chinese brands build their entire strategy around being fully JEDEC-compliant to make it easy for you to adopt their products.

The Reality of Chinese Manufacturing

I remember a client who was working on a budget-friendly consumer tablet. They were stuck between a rock and a hard place with their bill of materials8 (BOM) cost. The price of the Korean-brand eMMC they were using was killing their margin. They were very skeptical when we suggested testing a Chinese alternative. But after their engineers put the samples through rigorous performance and reliability tests, they were surprised. The Chinese part performed identically to the major brand they were using, but it came in at a 30% lower cost. That project shipped on time and, more importantly, under budget. This is not a one-off story; it's becoming more and more common.

Where They Shine: Application-Specific Reliability

It's also important to match the component to the application. You don't need a military-grade component for a children's toy. The key is understanding where these brands provide the most value.

| Application Category | Suitable for Chinese Brands? | Key Considerations |

|---|---|---|

| Consumer Electronics (Toys, Gadgets) | Yes, highly suitable | Cost is the primary driver. Performance is sufficient. |

| IoT Modules (Smart Home Devices) | Yes, in many cases | A good balance of cost, power consumption, and reliability. |

| Industrial Control | Caution advised | Depends on specific environmental and reliability needs. Test thoroughly. |

| Automotive / Medical / Aerospace | No, not recommended | Requires stringent, specialized certifications that these brands typically lack. |

How Can You Mitigate the Risks of Sourcing from New Brands?

Trying a new, lesser-known supplier can feel like a gamble. You're naturally worried about counterfeit parts9, inconsistent quality, and a lack of technical support when you need it most.

The best way to mitigate these risks is to partner with an experienced distributor and implement a strict qualification process. A good partner vets suppliers for you, and providing samples for your own in-house testing allows you to verify performance and reliability before making a commitment.

You should never switch a component blindly, especially not one as critical as memory. The "trust but verify" approach is essential. Over my career, I've helped countless clients navigate this process, turning a potential risk into a strategic advantage. It’s not about taking a leap of faith; it’s about taking calculated, manageable steps.

The Power of Qualification Samples

The single most important step is getting your hands on samples and testing them yourself. Datasheets are great, but real-world performance in your system is what matters. We always insist on providing our clients with qualification samples10 before they even think about a purchase order. Your engineers should put these parts through your standard validation process. This could include thermal cycling11, stress tests, data retention checks12, and performance benchmarks13. This process gives you objective data to make an informed decision. If the part passes your tests, you can have confidence in its quality.

Partnering with a Trusted Distributor

This is where we come in. With over 20 years of experience in this industry, our team has built relationships and a deep understanding of the global supplier landscape. We don't just find the cheapest part; we find reliable sources. We vet the factories, check their certifications, and understand their quality control7 processes. We act as your filter, saving you the immense time and risk of trying to find and validate these new brands on your own. Because we source directly from authorized channels, we can ensure full traceability and guarantee 100% authentic components.

A Step-by-Step Approach to Integration

A few years ago, a customer designing smart home plugs was hit with a sudden 40% price increase from their usual memory supplier. Production was at risk. They were very hesitant to try a Chinese brand we recommended. We walked them through a simple, step-by-step process:

- Identify the Project: We confirmed the smart plug was a perfect candidate—high volume and cost-sensitive14, but not mission-critical.

- Consult and Recommend: We provided datasheets for a specific Chinese eMMC that was a pin-for-pin compatible replacement.

- Sample and Qualify: We sent them free samples, which their engineering team tested for two weeks.

- Pilot Run: After the parts passed qualification, they placed a small order for a pilot production run of 500 units.

- Volume Production: The pilot run was successful, with no failures. They then moved to volume production with confidence.

That customer has now been using that Chinese brand for over two years without a single major issue. This methodical approach removes the gamble and replaces it with a predictable process.

When Are Chinese Memory Brands the Smartest Choice for Your Bill of Materials?

You know these alternatives exist, but you're not sure exactly when to use them. Is it always just about finding the cheapest possible component for every product you make?

Chinese memory brands are the smartest choice when you're under intense cost pressure for high-volume consumer electronics15. Think toys, low-end tablets, simple IoT devices, and promotional gadgets where every cent counts.

The decision to use an emerging brand isn't just about cost; it's about a strategic fit. It’s about being smart with your resources and not over-specifying components for the application. A common mistake I see is companies using a premium, expensive memory chip in a product that simply doesn't need that level of performance or endurance. That's like putting a sports car engine in a golf cart. It works, but you've wasted a lot of money.

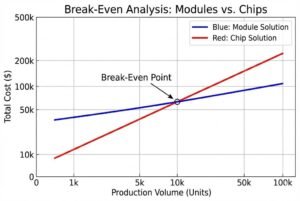

The High-Volume, Low-Margin Game

In the consumer electronics market, the margins are often razor-thin. When you're producing hundreds of thousands or even millions of units, saving $0.10 on a single memory chip can translate into tens or hundreds of thousands of dollars in savings. This can be the difference between a profitable product and a failed one. This is the sweet spot for Chinese brands. They are built for this game, offering "good enough" performance and reliability at a price point that the major brands often can't match.

A Strategic Plan B for Supply Chain Shocks

Beyond cost, having a qualified alternative supplier is a powerful supply chain strategy16. We all remember the massive component shortages and price hikes over the last few years. Companies that had only one approved memory supplier were stuck. They either had to halt production or pay outrageous prices on the spot market. However, the clients we had worked with to pre-qualify a Chinese brand as a backup had a Plan B. They were able to switch to their alternative source and keep their production line6s moving. It’s not just about cost savings; it’s about resilience.

If you are facing extreme cost pressure, and your product is not for military or aerospace-grade applications, we can provide you with high-quality, cost-effective samples of Chinese brands for testing. It’s a no-risk way to see if this strategy is right for you.

| Use Chinese Memory When... | Avoid Chinese Memory When... |

|---|---|

| The product is a high-volume consumer good. | The product is for automotive, aerospace, or medical use. |

| The primary driver is aggressive cost reduction. | Extreme reliability and data longevity (10+ years) are required. |

| The application is not mission-critical or life-sustaining. | The part requires specific, hard-to-get certifications. |

| You need a backup supplier for supply chain stability17. | Your end-customer contract explicitly forbids components from certain regions. |

Conclusion

Emerging Chinese memory brands are a viable Plan B for many consumer applications. With proper vetting, partnership, and testing, they offer a powerful way to manage costs and secure your supply chain.

Explore how these brands can provide cost-effective alternatives without compromising quality. ↩

Understanding JEDEC standards can help you ensure compatibility and reliability in your components. ↩

Learn how to assess the value of memory components to optimize your procurement budget. ↩

Discover strategies to optimize your procurement budget while maintaining quality. ↩

Understanding these risks can help you mitigate potential disruptions in your supply chain. ↩

Learn about factors that can impact the efficiency of your production line. ↩

Explore effective quality control measures to ensure reliable component sourcing. ↩

Explore how to effectively manage and optimize your bill of materials for cost savings. ↩

Discover methods to protect your production from counterfeit components. ↩

Discover the significance of qualification samples in ensuring component reliability. ↩

Understand the importance of thermal cycling in ensuring component reliability. ↩

Learn the process of data retention checks to ensure long-term reliability. ↩

Learn how to perform benchmarks to validate the performance of new components. ↩

Understanding cost sensitivity can help you make informed decisions about component sourcing. ↩

Explore the unique challenges and strategies for success in high-volume production. ↩

Learn about strategies that can enhance your supply chain resilience and efficiency. ↩

Explore strategies to maintain stability in your supply chain amidst challenges. ↩